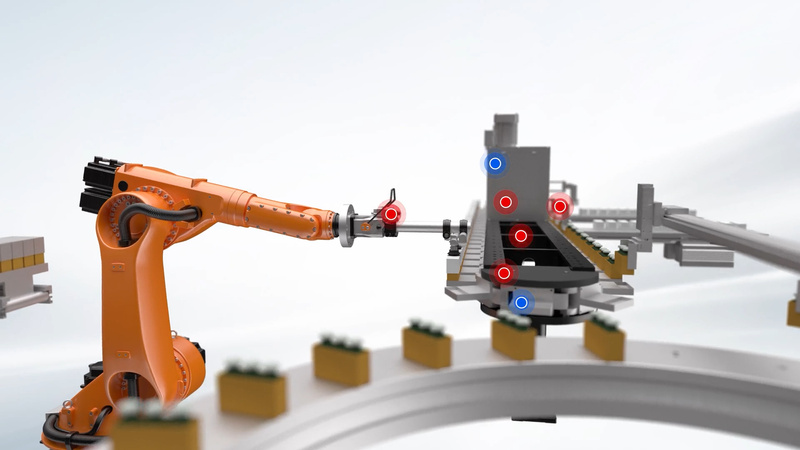

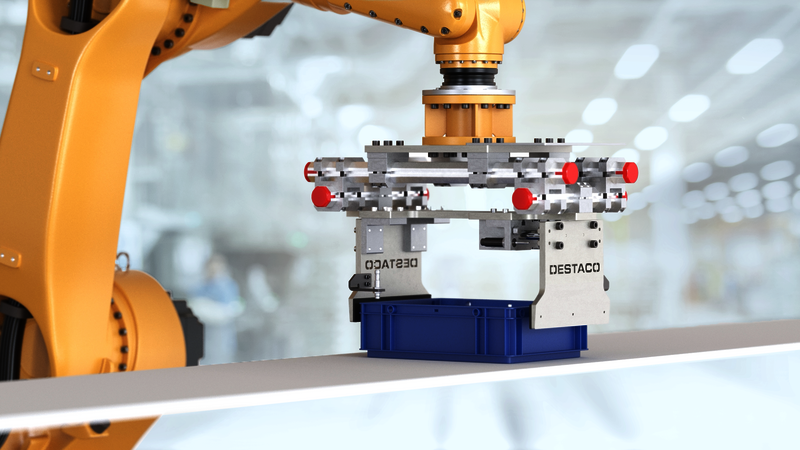

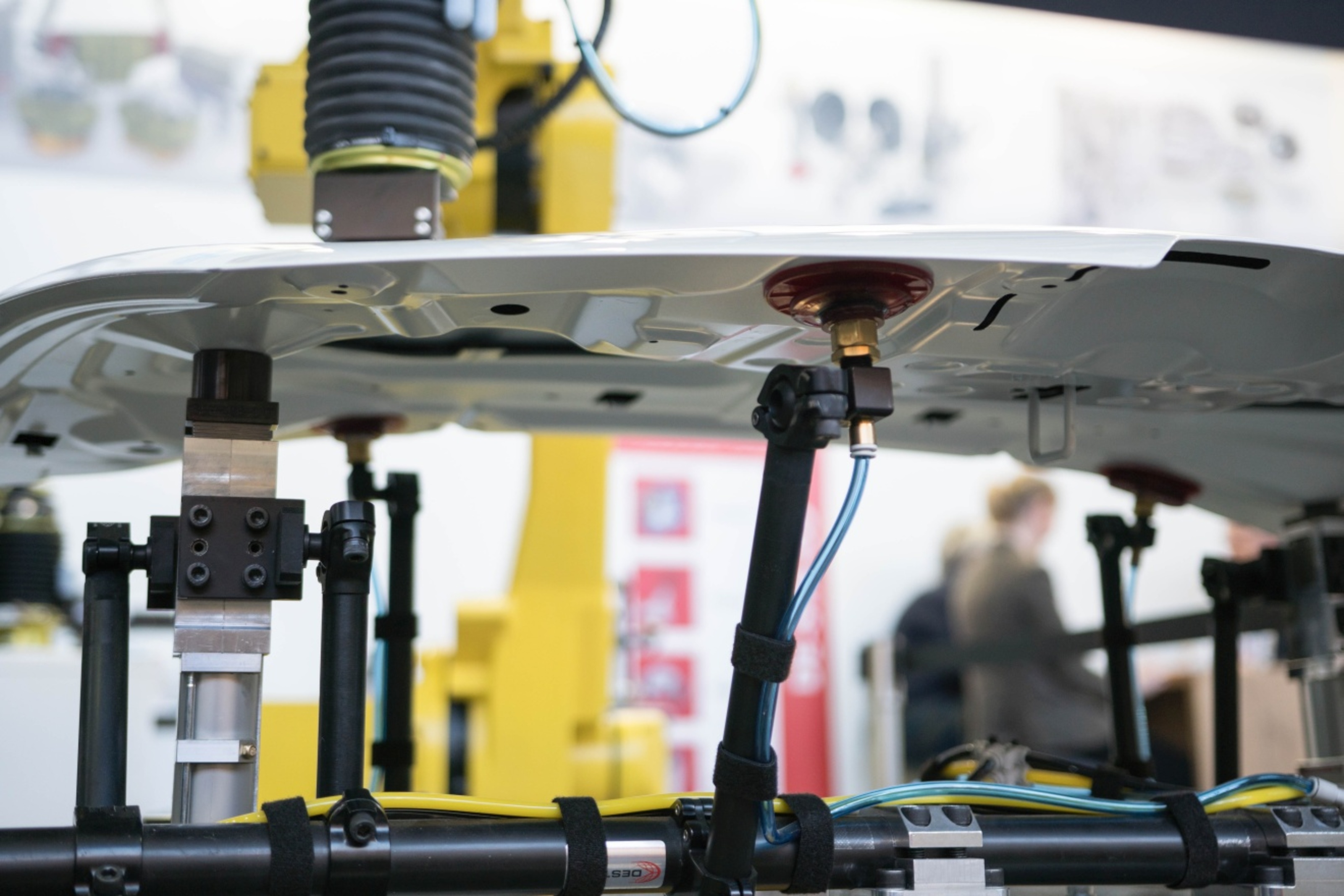

In the automotive industry, ACE's shock absorbers and Destaco's clamping and gripping components illustrate a perfect synergy within the manufacturing process. They ensure top-notch efficiency and quality, particularly during car body assembly, where precise automated welding and fastening of vehicle components are critical. Destaco's range of electrically or pneumatically operated clamps, grippers and sheet metal grippers holds parts in exact position, while ACE's industrial shock absorbers proficiently manage the kinetic energy of robot movements to guarantee precision in robot motion and welding points, cycle after cycle. Notably, ACE's adjustable and self-compensating shock absorbers diminish the transmission of unwarranted forces that could compromise weld quality, while Destaco’s pneumatic power clamps have the ability to adjust to different thicknesses of metals using its tolerance compensating capability. All of this results in less wear and tear inside and out to the robot, as well as enabling more uptime due to eliminating the need to adjust tolerances in clamping applications.

Enhancing Efficiency in "The Marriage" of Automobile Assembly

The "marriage" phase of automobile production, where the powertrain meets the body, also benefits from Stabilus and Destaco solutions. Varied positioning systems courtesy of Destaco, paired with ACE's industrial gas springs, perform flawlessly in aligning the engine and chassis, lightening workloads and preventing installation errors. From Destaco’s conveyors and feed escapements to slides, indexers, rotaries and servo positioners all the way to the clutches for a wide variety of requirements and loads, Destaco’s solutions always ensure the precise placement of the engine in the chassis. ACE’s push and pull type Industrial gas springs perform additional tasks that support or replace the muscle power of the operating personnel by facilitating the lowering of the engine into the engine compartment. This prevents damage or misalignment during installation.

Making Customers Champions of Competitiveness

The collaborative approach to integrating Destaco's clamping, gripping, and positioning systems with ACE's innovative motion and vibration control technologies ensures highly efficient, top-tier solutions across mechanical and plant engineering. Stabilus Group clients enjoy reduced rejection rates, fewer damages, and increased production consistency not only in the automotive sector but broader industrial automation processes. By providing a comprehensive and future-proof array of automated assembly line components from a single source, Stabilus Group sets a new standard for customer competitiveness.

Sustainably modernize and optimize entire production lines with the combined services of ACE and Destaco

Destaco end effectors in use for robotic grinding

Find our solutions for your industry

Discover Stabilus 4 Automation

With Stabilus4Automation, the Stabilus Group presents a customized synergy concept for the industry.

Start your project with us - we look forward to hearing from you!

Subscribe to our newsletter

Thank you for your interest in Stabilus!

Subscribe to our newsletter and receive regular exclusive insights, product news, and expert knowledge about the Stabilus Group's automation solutions – directly in your inbox.

With your consent, we are allowed to send you information by email. You can revoke your consent at any time if you no longer wish to receive emails.

To subscribe, please fill out the form and click “Register”. You will then receive a confirmation e-mail. Please confirm your subscription by clicking the link in that e-mail (double opt-in).

-

Mechanical engineering and automation

Industries such as machine tools and laser technology, semiconductors as well as plant engineering and automation technology have many individual requirements - but also some overlaps.

-

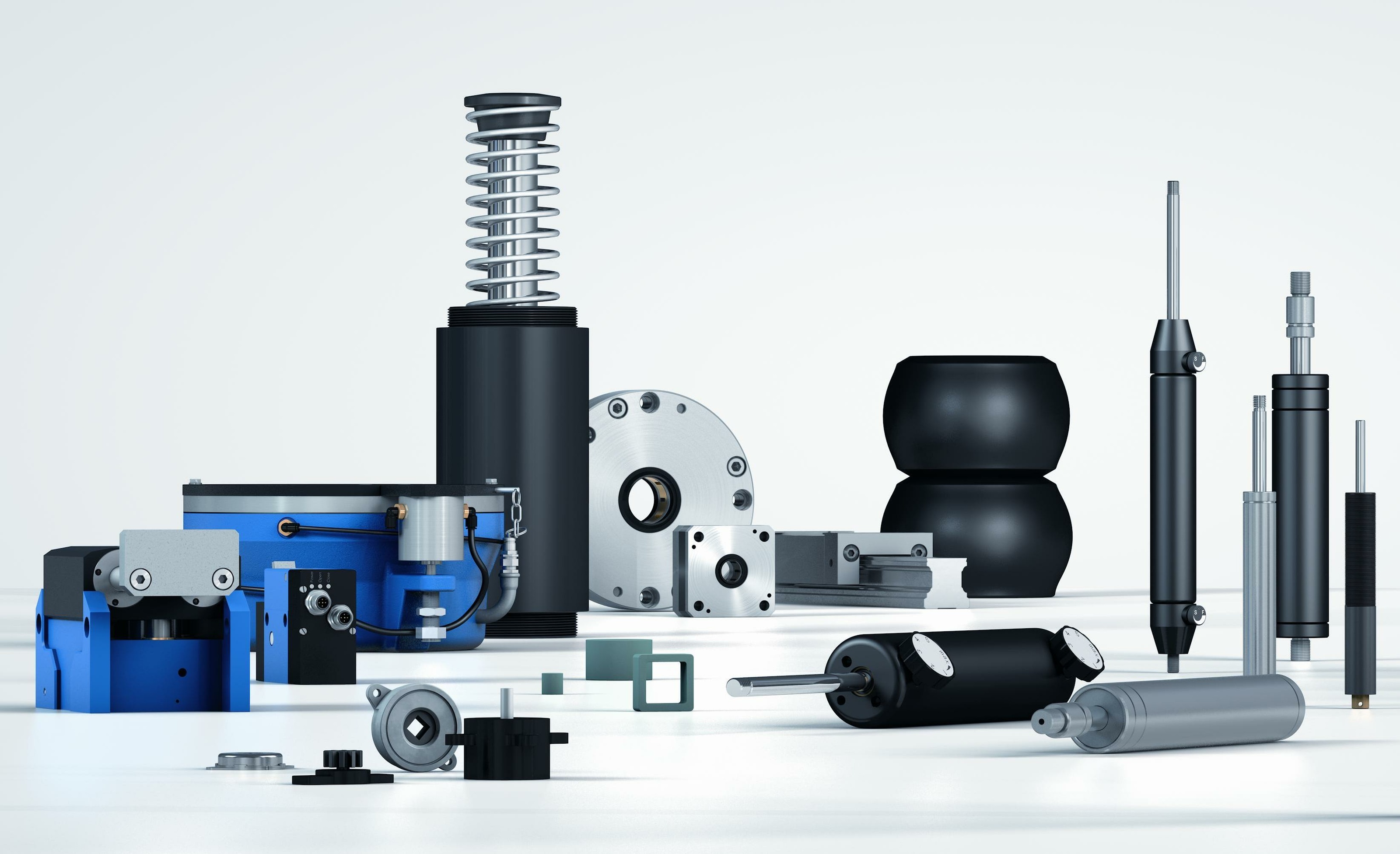

ACE

Expert in industrial damping and motion control with solutions for the most demanding applications and excellent customer service.

-

Destaco

A global leader in the design and manufacture of high-performance automation, workholding, and remote handling solutions.