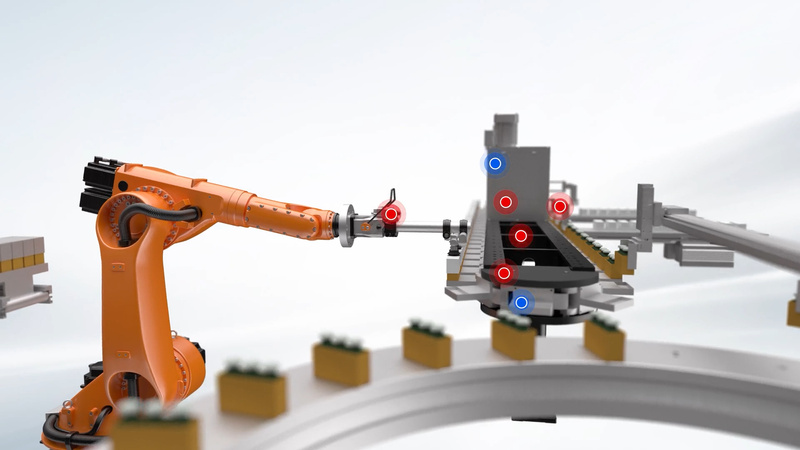

'Stabilus4Automation' serves as the cornerstone of Stabilus Group's introduction of its bespoke synergistic offerings for the automation industry. Beginning June 2025, this unification of benefits will be unveiled for the first time at a series of major international expos, including Automatica in

Munich, Germany, AMTS in Shanghai, China, among others. This synergy is achieved through the combination of premium components from the esteemed brands within the group—Stabilus, ACE, Destaco, Fabreeka, and Hahn Gasfedern. This collaboration results in a new echelon of superior automation solutions,

conveniently offered through a single provider for both system integrators and end-users.

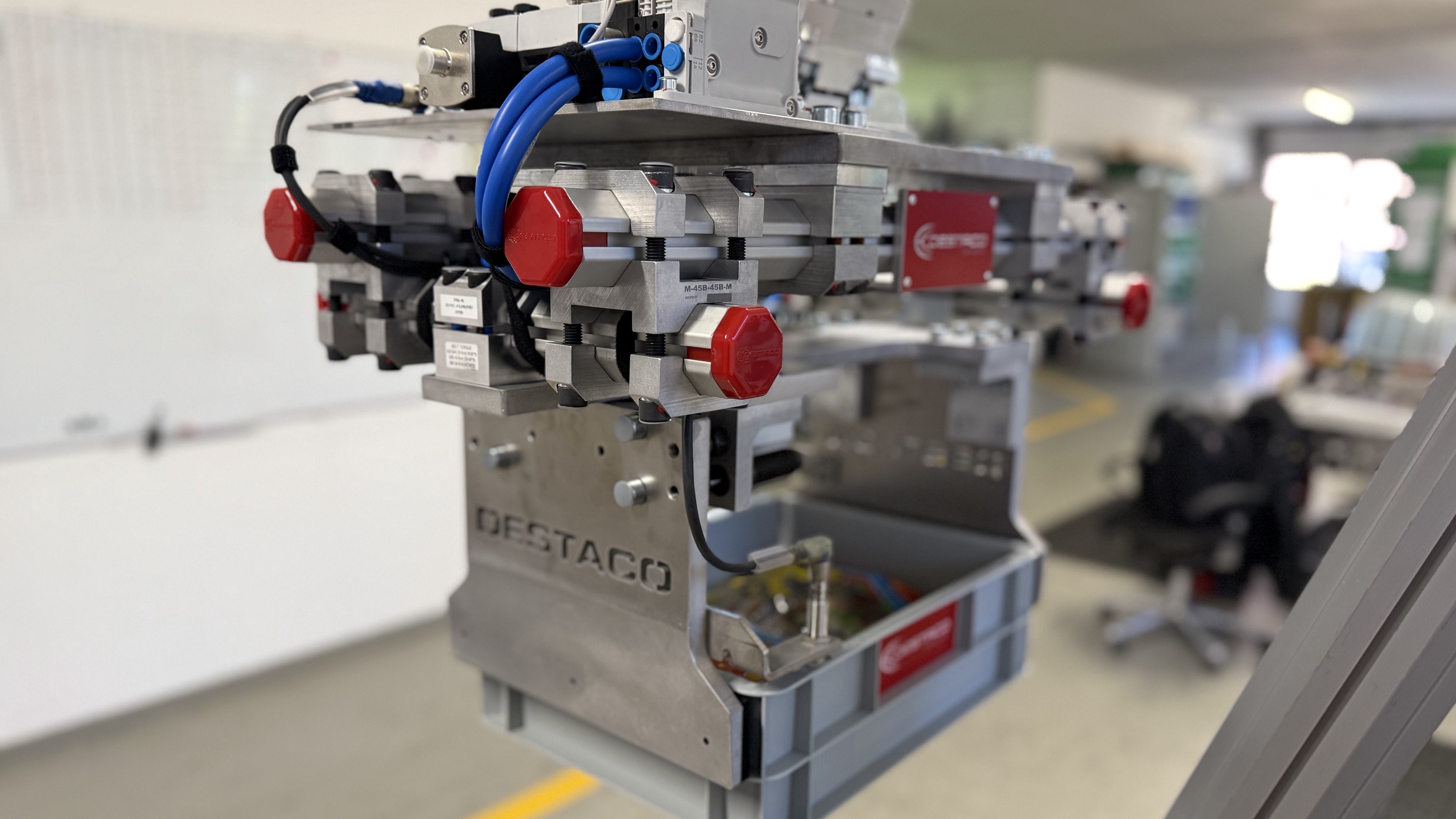

The first outcome of these synergies stems from the expertise and high-quality products of the ACE and Destaco expert brands, resulting in a collaborative solution developed by both companies. Destaco, recognized for its expertise in clamping and gripping technology, and ACE, specializing in damping

solutions, have worked together to enhance an existing Destaco product - the DBG Series Bag Gripper. These grippers are highly adaptable, capable of handling both boxes and bags, as well as serving in a variety of other processes. Renowned for being among the fastest and most reliable solutions on the

market, the DBG bag gripper series now benefits from the integration of ACE’s damping solutions. This collaboration signals the beginning of additional joint developments that Stabilus Group is actively pursuing, soon to be introduced to the automation industry. Customers stand to gain significantly,

enjoying seamless solutions from a single source and reaping the rewards of newly created synergies through collaborative innovation.

Peak performance: Longer life and less energy consumption in Destaco's box gripper, enhanced with ACE MC shock absorbers

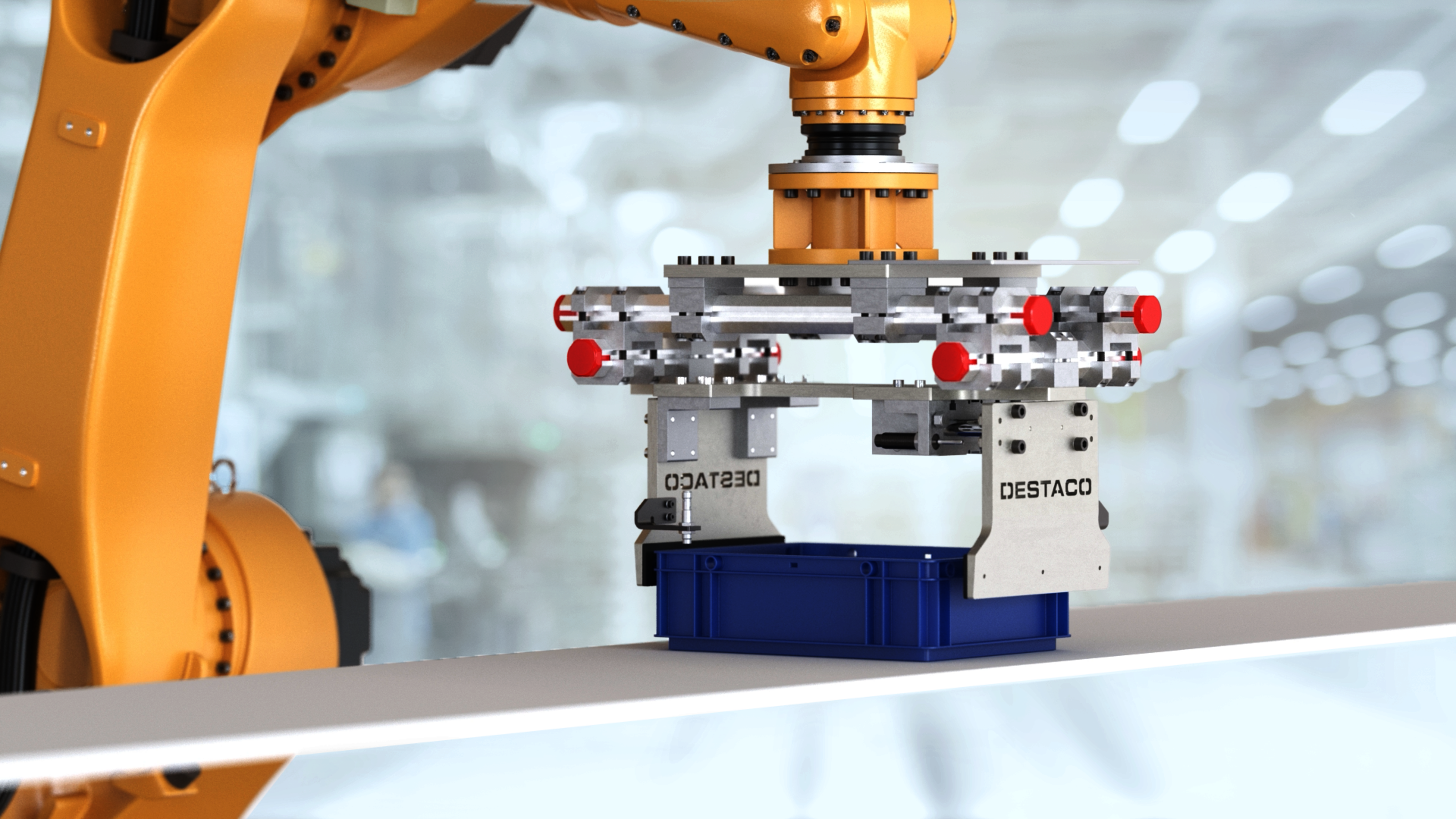

DBG series bag grippers for high speed and reliable transfers

Destaco bag grippers are ideal for pick-and-place palletizing applications, efficiently handling and stacking boxes or bags. The DBG series features a lightweight, field-adjustable design, commonly used in the food industry for consumer goods packaging, as well as in various unique applications across

other industries. Recognizing the importance of speed in these processes, Destaco grippers stand out for their rapid actuation, enabling reduced cycle times. When integrated with robotic automation systems, these grippers can palletize up to 30 boxes per minute. To ensure safe transfers at high speeds, the

DBG series incorporates an enclosed pneumatic toggle-lock power clamp with built-in opening and closing detection. This design securely holds boxes even in the event of air pressure loss, eliminating the need for heavier, more complex, and costly linkage-based systems.

Prioritizing user convenience and flexibility, the DBG series offers several options, including pallet pickup, interleaf transfer mechanisms, and either spring- or pneumatically-controlled retention systems. To further cater to diverse requirements, an assortment of valve and control packages is available,

ensuring optimal performance tailored to specific applications.

Find out more about the DBG series here

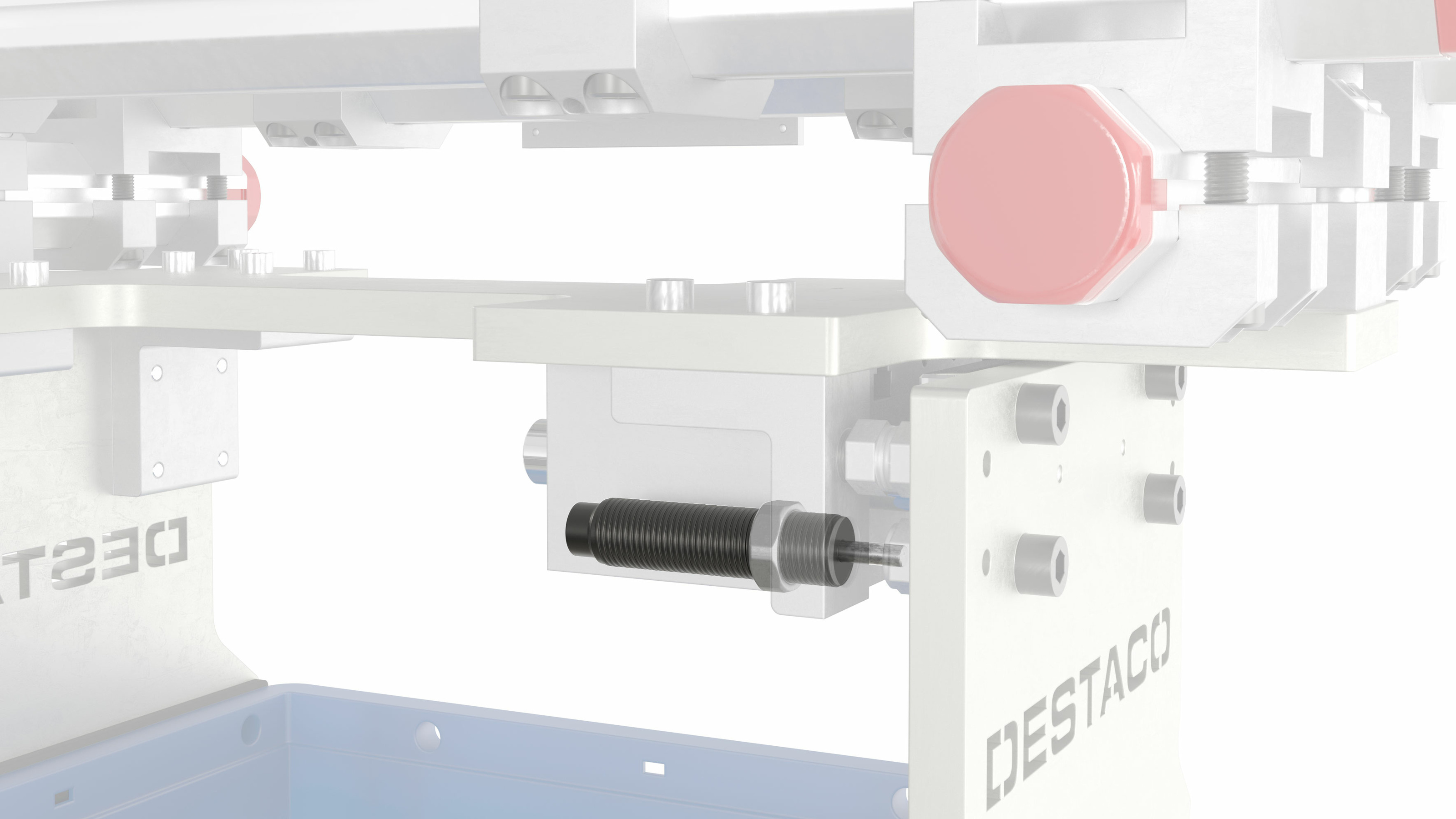

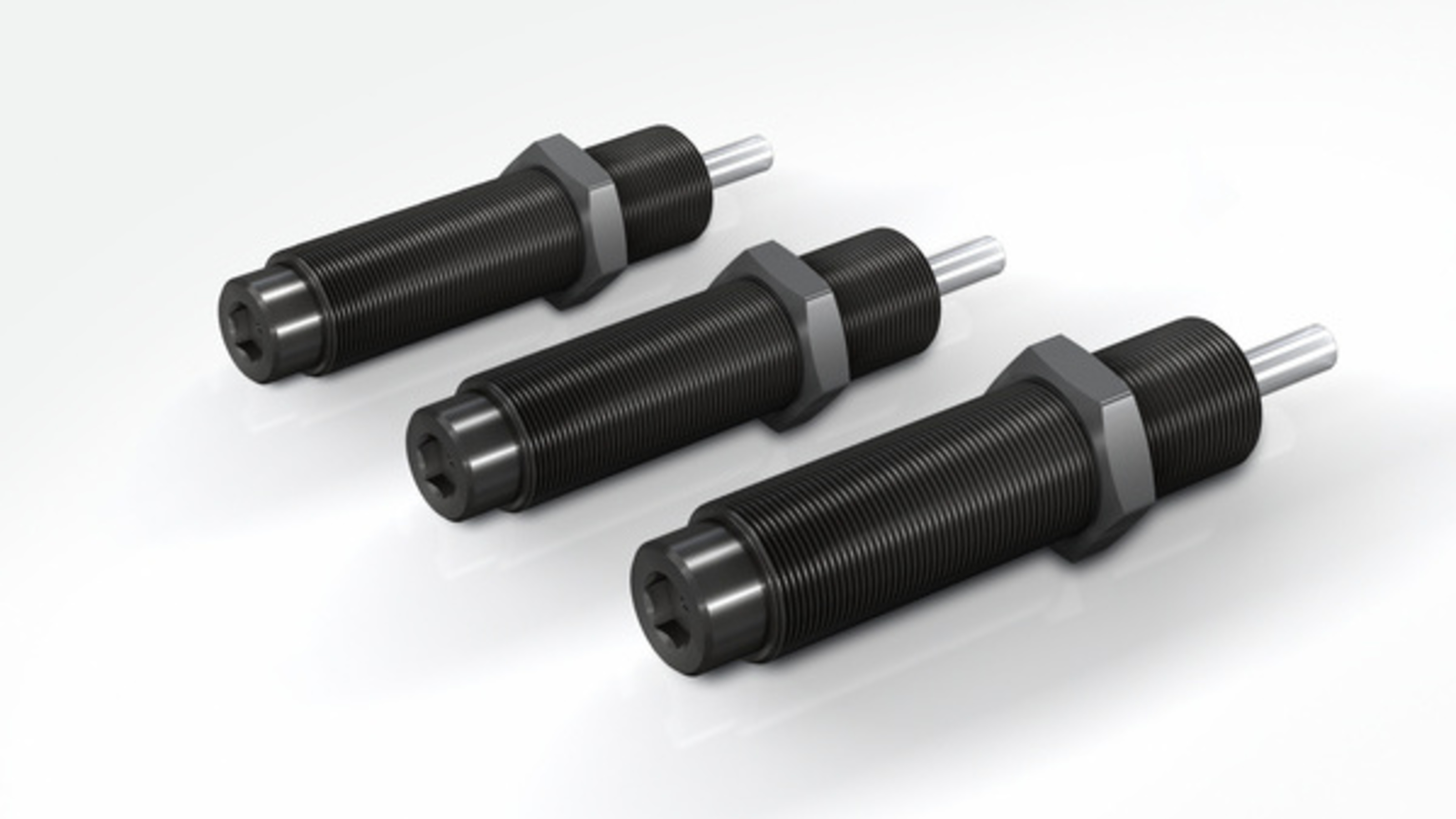

Advantages from integrating ACE miniature shock absorbers

Destaco's automation experts, alongside damping specialists from ACE, have engineered a tailored handling solution, emerging as an exceptionally effective end-of-arm tool (EOAT). By incorporating MC series miniature shock absorbers from ACE into the EOAT design, they've achieved a solution that not only

optimizes handling for items of various sizes and weights but also enhances protection for both the peripherals and the goods being transported. The self-adjusting dampers of the MC series are known for their ability to dissipate maximum energy in the tightest of spaces. Thanks to rolling diaphragm

technology, they have an extremely long service life.

This integration of gripping technology with superior damping mechanisms significantly alleviates stress on the equipment's structure, leading to shorter cycle times and improved durability. As a result, customers benefit from enhanced goods protection during every cycle, and system operators enjoy the

advantages of longer-lasting grippers and peripherals, reduced maintenance, and improved overall energy efficiency. The use of finely tuned shock absorbers allows for the use of smaller pneumatic cylinders, which reduces both initial and ongoing operational costs associated with electricity and compressed

air consumption.

Another advantage is the compact design of ACE's miniature shock absorbers, making them perfectly suited for retrofitting into existing setups. Ultimately, this ensures that customers can source all solutions, including replacements or enhancements, from a single provider, streamlining the process and

guaranteeing an optimized, comprehensive handling solution.

Find out more about MC shock absorbers here

DESTACO BOX GRIPPER WITH MINIATURE SHOCK ABSORBERS FROM ACE

Experience Stabilus4Automation live at international trade shows

Under the umbrella of the Stabilus Group, the complementary expertise of expert brands like Destaco and ACE brings numerous advantages. Destaco, a global leader in developing high-performance automation, workholding, and remote handling solutions, addresses key operational questions such as, "How can this

box or bag be transported from A to B as quickly as possible, and how can it be securely gripped?" Meanwhile, ACE, a pioneering force in industrial damping technology since 1963 with a rich history in automation applications, enhances safety and efficiency. ACE's role involves providing engineering acumen

and tailored product solutions to effectively handle concerns like, “How can I optimally decelerate and mitigate the forces at play here?”

This collaborative strategy, operating under the initiative ‘Stabilus4Automation’, synthesizes the capabilities of each company to produce a cohesive product that delivers substantial value to the customer. This synergy not only enhances individual product offerings but creates integrated solutions that

elevate overall performance and customer satisfaction.

In conjunction with a range of products from Fabreeka and Hahn Gasfedern, the potential for advancements in the automation industry is boundless. These innovative solutions will be showcased at several upcoming trade shows, including Automatica in Munich, Germany, AMTS in Shanghai, China, and Automate in

the USA. Attendees at these events will have the opportunity to see how collaborative efforts result in new, efficient solutions that not only enhance efficiency and reduce energy expenses but are also offered from a single source.

Find our solutions for your industry

Discover Stabilus 4 Automation

With Stabilus4Automation, the Stabilus Group presents a customized synergy concept for the industry.

Start your project with us - we look forward to hearing from you!

Subscribe to our newsletter

Thank you for your interest in Stabilus!

Subscribe to our newsletter and receive regular exclusive insights, product news, and expert knowledge about the Stabilus Group's automation solutions – directly in your inbox.

With your consent, we are allowed to send you information by email. You can revoke your consent at any time if you no longer wish to receive emails.

To subscribe, please fill out the form and click “Register”. You will then receive a confirmation e-mail. Please confirm your subscription by clicking the link in that e-mail (double opt-in).

-

Mechanical engineering and automation

Industries such as machine tools and laser technology, semiconductors as well as plant engineering and automation technology have many individual requirements - but also some overlaps.

-

ACE

Expert in industrial damping and speed control with excellent customer service and solutions for the most demanding applications.

-

Destaco

A global leader in the development and manufacture of high-performance automation, workholding and remote handling solutions.